The World’s Best Technology

- HOME

- The World’s Best Technology

Adhering to meet strict quality standards

We manufacture jet engine components and special jigs, as well as components and special jigs for space stations and rockets in the aerospace sector, where the highest technology standards are required.

Utilizing “difficult-to-cut material” processing technologies cultivated in the aerospace field, we manufac-ture products in fields requiring high reliability, such as semiconductor manufacturing equipment, electric power facilities, and medical equipment. Based on our accumulated precision processing technologies, we support high-quality monozukuri.

Advanced x High Quality

Deals with major Japanese manufacturers and other overseas companies

A turning point for our company, which used to manufacture special drills, was the start of a business deal with IHI Corporation. Beginning with the manufacture of jigs and tools for large jet engines for aircraft, we have also been entrusted with the machining of parts.

We then acquired aircraft quality certifica-tion, which is extremely difficult to obtain. We are now involved in the machining and manufacture of engine components for various types of aircraft ranging from business jets to large passenger aircraft, and the sales from this field accounts for 70% of our sales.

Demand for aircraft in emerging countries is in-creasing, and domestic and overseas demand is expanding and diversifying as a result of the downsizing and improved fuel efficiency of jets. In response to this situation, a new plant was completed in July 2016. We have put in place a system to meet the expectations of our customers in Japan and overseas through cutting-edge, advanced technology.

Technological and development capabilities

Technologies used in space stations, power generation facilities, and medical equipment

We are applying the technologies we have refined in aircraft part processing and manufacturing to a wide range of fields.

Our products are also used in space stations and rockets, semiconductor manufac-turing equipment, various plants, and industrial machinery such as power generation facilities. We also manufacture components for MRI and other medical equipment.

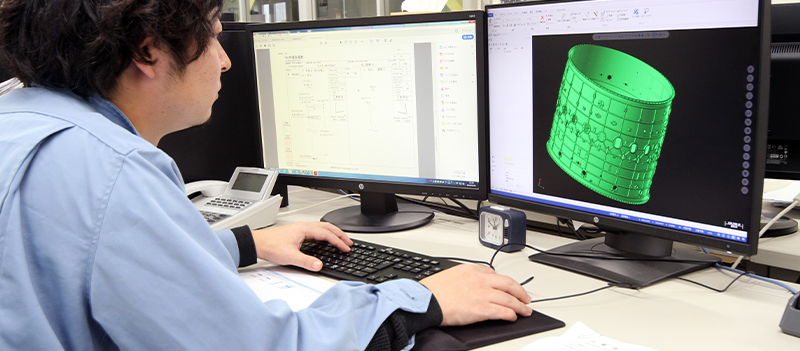

One of our greatest strengths is our ability to consistently design and develop not only parts, but also jigs that are essential for manufac-turing. This allows us to flexibly respond to various customer needs.

We have the technological capa-bilities to provide products in fields requiring high reliability, such as aerospace, industrial machinery, and medical equipment.

Expertise to process difficult-to-cut materials with micron accuracy

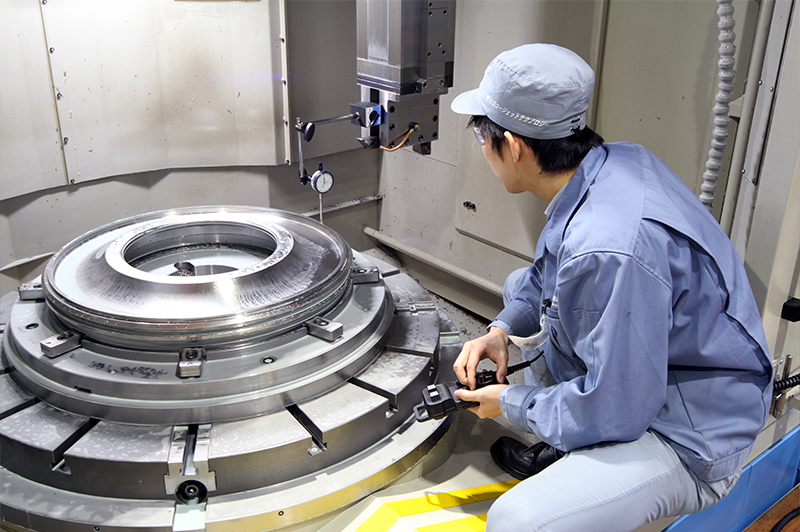

From palm-sized parts to large parts that span several meters

We offer a wide variety of products, but they all have one thing in common. They are realized by “diffi-cult machining technology that is only possible through our expertise.”

For example, hard metals such as Inconel and titanium are used for aerospace components to withstand harsh environments. These “difficult-to-cut materials” cannot be cut without a great deal of knowledge. In order to cut and process diffi-cult-to-cut materials with micron accuracy, knowledge based on accumulated experience is indispensable. This is why our products are used in a wide range of fields.

Please experience the best part of “high-precision monozukuri using advanced technologies” through our company.